No products in the cart.

As an esports enthusiast and technology geek, I’ve witnessed a fascinating revolution in gaming peripherals. The humble mousepad has transformed from a simple fabric surface to a cutting-edge piece of precision engineering. Have you ever wondered how a piece of tempered glass becomes the secret weapon of top-tier FPS players?

In the world of competitive gaming, where milliseconds can separate victory from defeat, every technological advantage counts. Glass mousepads have emerged as the ultimate performance enhancer, turning ordinary mouse movements into surgical strikes of pixel-perfect precision. But the journey from molten sand to esports glory is far more complex and fascinating than most players realize.

This blog will take you behind the scenes of an engineering marvel. We’ll dive deep into the intricate process of creating tempered glass mousepads – exploring how raw materials are transformed, how cutting-edge manufacturing techniques produce an surface that’s simultaneously smooth as silk and tough as armor. I’ll walk you through the scientific artistry that turns a simple piece of glass into what FPS players now call their “physical cheat code”.

I. Choose Substrate Glass and Pre-processing

- Float Glass: Produced from high-purity silica sand, thickness 3-6mm, Mohs hardness ≥9H, light transmittance ≥92% for optical sensor compatibility.

- Cutting & Edge Polishing: Laser-cut to gaming-standard sizes (e.g., 450×400mm, 490 x 420mm), CNC-machined edges to R15mm curvature to prevent wrist abrasion.

II. Micro-Etching Surface Treatment Process

1. Acid-Resistant Ink Screen Printing

- Pattern Design: Grid or stripe-shaped protective layer printed (dot diameter 0.4mm, spacing 0.8mm).

- Curing: Dried at 120-160°C for 30 minutes to form acid-resistant barriers.

- UV art print: Precise control of ink droplet spraying by piezoelectric printheads (minimum droplets up to 2 picoliters), realizing high resolution of over 1200 dpi and accurate reproduction of artwork details.

2. Acid Etching

- Etching Solution: Hydrofluoric acid (55% concentration) 20-30 parts, sulfuric acid (98%) 10-20 parts, nitric acid (65%) 10-20 parts, ammonium bifluoride 5-15 parts, water 40-50 parts.

- Parameters: Immersed at 25-30°C for 20-30 minutes, creating uniform more than 2μm-deep micro-pits to optimize friction and optical tracking.

- Cleaning: Neutralized with 5% sodium hydroxide (NaOH), high-pressure water rinsed to pH 7.

3. Frosting Reinforcement

- Frosting Solution: Ammonium bifluoride 20-40 parts, ammonium fluoride 10-30 parts, barium sulfate 10-15 parts.

- Surface Roughness: Processed for 2-2.5 minutes to achieve Rsm ≤10μm for balanced glide and control.

III. Functional Coating Technology

- Anti-Fouling Coating

- Nano-Silica Coating: 50nm-thick SiO₂ layer with hydrophobicity (contact angle ≥110°), reducing sweat residue by 70%

- Noise Reduction Layer

- Polyurethane (PU) Coating: 0.1-0.2mm thickness, reducing sliding noise to ≤25dB

Attention: The coating may peel off after a period of use and cleaning the surface with detergent or alcohol may damage the coating.

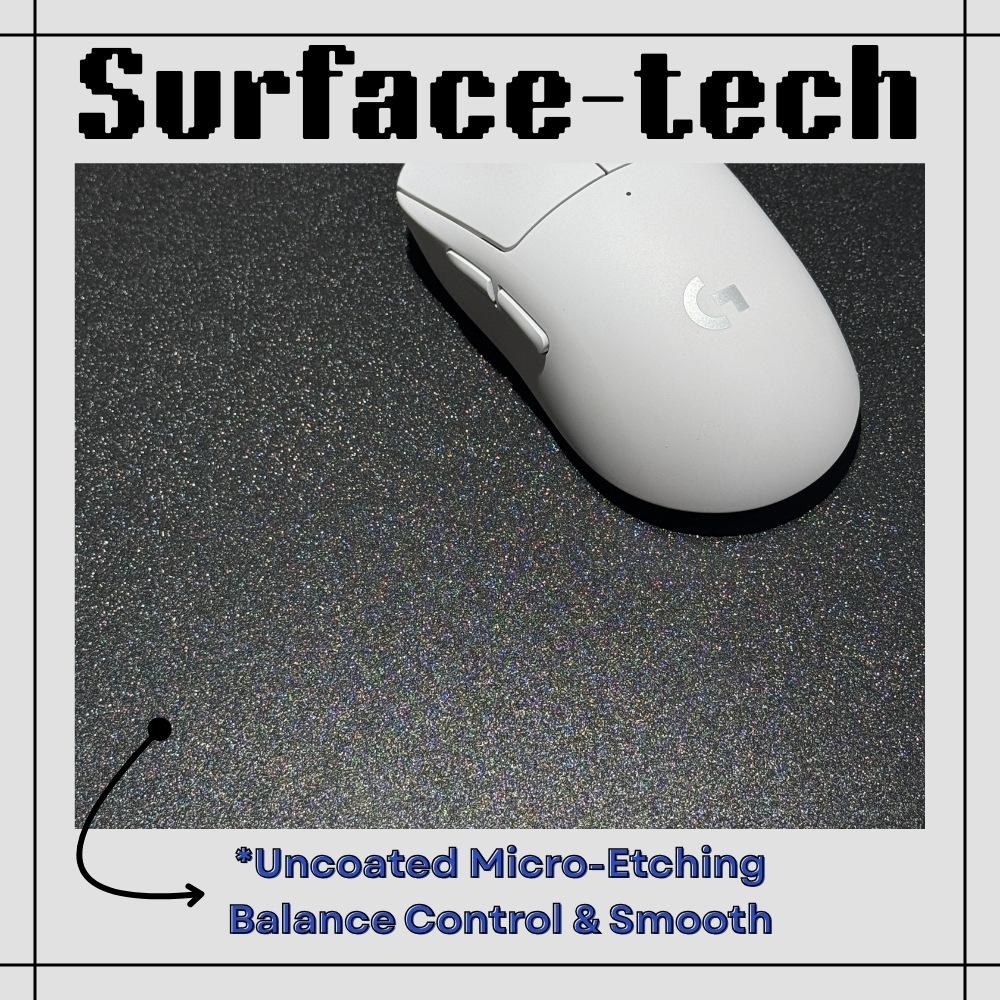

IV. Skadira innovative surface technology

In order to avoid any coating peeling off, skadira precisely controls the micro-etched surface to optimize mouse gliding and incorporates hydrophobic technology to bring anti-smudge, noise reduction and non-abrasive mouse pad skates even without additional coatings.

V. Non-Slip Base and Structural Optimization

- Rubber Base Assembly

- Adhesive: 3M polyurethane glue bonds honeycomb-patterned rubber (Shore hardness 60±5), friction coefficient ≥5N.

VI. Quality Control and Testing

- Optical Performance

- Laser reflectometry verifies texture uniformity, ensuring zero sensor tracking loss (≥8000Hz sampling rate).

- Durability Testing

- Simulated 100,000 swipes (500g pressure), surface wear rate ≤0.3%.

- Environmental Adaptability

- Tested at 35°C/80% humidity; rubber base friction ≥5N.

VII. conclusion

As our journey through glass mousepad technology concludes, I’m amazed by how innovation transforms simple materials into gaming precision. The real game-changer? Skadira innovative surface technology.

Unlike traditional approaches that rely on multiple coatings prone to peeling, Skadira has revolutionized mousepad engineering. By precisely controlling micro-etched surfaces, they’ve created a solution that optimizes mouse gliding, incorporates hydrophobic technology, and eliminates the need for additional coatings. This means gamers get an anti-smudge, noise-reducing surface that maintains performance integrity over time.

What began as a quest to enhance gaming peripherals has become a testament to engineering brilliance – proving that in competitive gaming, the smallest technological advantage can make the difference between victory and defeat.